PCB Fabrication

Located in the core area of South China's PCB industry cluster, EDADOC Zhuhai PCB Factory benefits from the highly-skilled workforce and well-established supply chain. Phase 1 has been fully put into operation, specializing in high-quality, quick-turnaround PCB prototype and mass production for multi-layer, high-speed, high-precision, HDI, etc. The phase 2 will focus more on medium and large volumes, committed to promoting technological progress in the PCB industry. The delivery time for 12-20L PCB is as fast as 8 days, setting a new benchmark in speed and quality.

Our PCBs are widely used in ATE, AI computing, optical modules, servers, industrial control, telecommunications, automotive, and medical equipment.

Board Making Advantages

PCB of high-end, quick turnaround and mass production

High-end and batch PCB production for 2-120 layers

8-day turnaround for boards with 20 layers or fewer

Core team with over 20 years of industry management experience

Minimum line width and line space: 30/30um

Thickness-to-aperture of 75:1

Long-term inventory of conventional FR4 and high-speed materials

Newly imported advanced equipment and Thousand-Level Clean Room

Technical Capabilities

Process Parameters

| Project | Process parameters |

|---|---|

| Layer | 2-120 L |

| Board Thickness | 0.3-10mm |

| Maximum size | 660*1250mm |

| Mechanical hole aperture | ≥0.11mm |

| Laser hole aperture | 0.06mm |

| HDI type | 1+n+1, 2+n+2, 3+n+3, any order HDI |

| Thickness-to-aperture | 75:1 |

| Interlayer alignment (High Layer Count) | 4mil |

| Minimum line width and line space | 30/30um |

| Impedance tolerance | ±5% |

| Back drilling STUB tolerance | 1-5mil |

| Routing tolerance | ±0.05mm |

| Bow and twist | ≤0.5% |

| Copper Clad Laminate (CCL) | Conventional FR4, M4/M6/M7/M8、IT958G/968/988GSE、S7439C、TU883+/933+、TU862HF、EM890K、EM892K2、RO4350, etc |

| Surface treatment | HASL,lead-free HASL(LF-HASL),Immersion gold,Immersion tin,Immersion silver,Gold plating,Electroless Nickel/Electroless,OSP,Immersion gold+OSP |

| Special process | Blind vias and buried vias, Stepped hole, Metal base PCB, Embedded resistor and capacitor, Mixed - laminate, Rigid-flex printed circuit board, Back drilling, Gold fingers, POFV(plating over filled via), Partial gold - plating |

Production Cycle

| Number of layers | Urgent | Template | Batch |

|---|---|---|---|

| 2L | 48h | 5days | 9days |

| 4L | 3days | 6days | 10days |

| 6L | 3days | 6days | 11days |

| 8L | 4days | 7days | 11days |

| 10L | 4days | 7days | 12days |

| 12L | 5days | 8days | 12days |

| 14L | 5days | 8days | 12days |

| 16L | 5days | 8days | 12days |

| 18L | 6days | 8days | 12days |

| 20L | 6days | 8days | 12days |

| 22L | 8days | 12days | 16days |

| 24L | 8days | 12days | 16days |

| 26L | 8days | 12days | 16days |

| 28L | 8days | 12days | 16days |

| 30L | 8days | 12days | 16days |

| 32L | 10days | 14days | 18days |

| 34L | 10days | 14days | 18days |

| 36L | 10days | 14days | 18days |

Note: Please contact our staff for the specific delivery time.

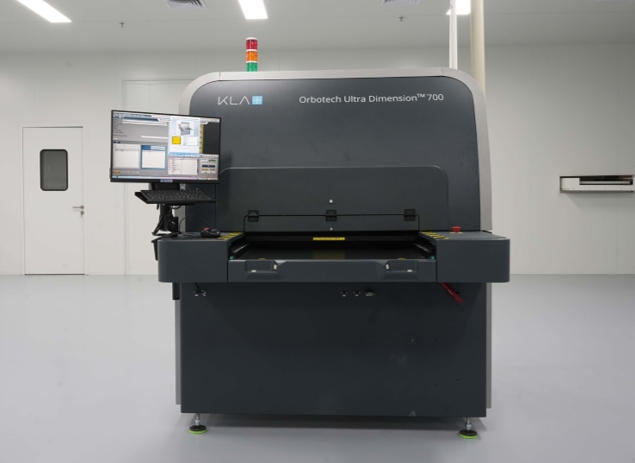

PCB Factory Equipment

Orbotech LDI High-precision Exposure Machine

Vacuum Twin Fluid Etching Line

Germany Lauffer Vacuum high temperature pressing machine

Germany Schmoll CCD Drilling Machine

CCD Electromagnetic Bonding Machine

Mitsubishi Laser Drilling Machine

X-Ray Target Drilling machine

ORC Solder Mask Exposure Machine

Sixteen-Axis Ceramic Grinding Machine

Orbotech AOI

Germany ATG Flying Probe Testing machine

AVI

Product Display